Morphotonics supplies commercially proven nanoimprint lithography equipment, powered by extensive process knowledge, and a diverse portfolio of materials.

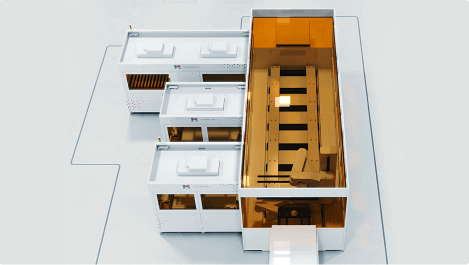

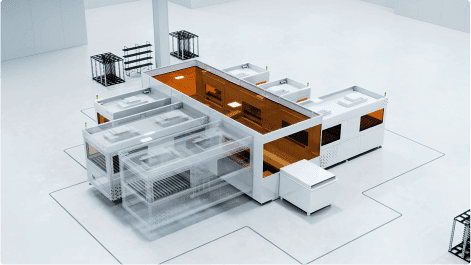

World’s largest area nanoimprint equipment

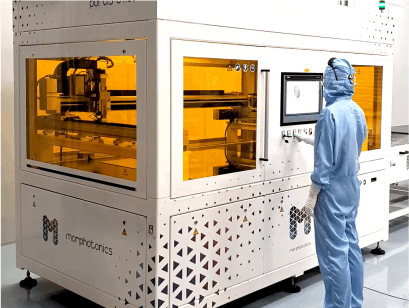

Our innovative solutions range from standalone nanoimprint lithography equipment for R&D and pilot production, to fully integrated nanoimprint platforms for high-volume production.

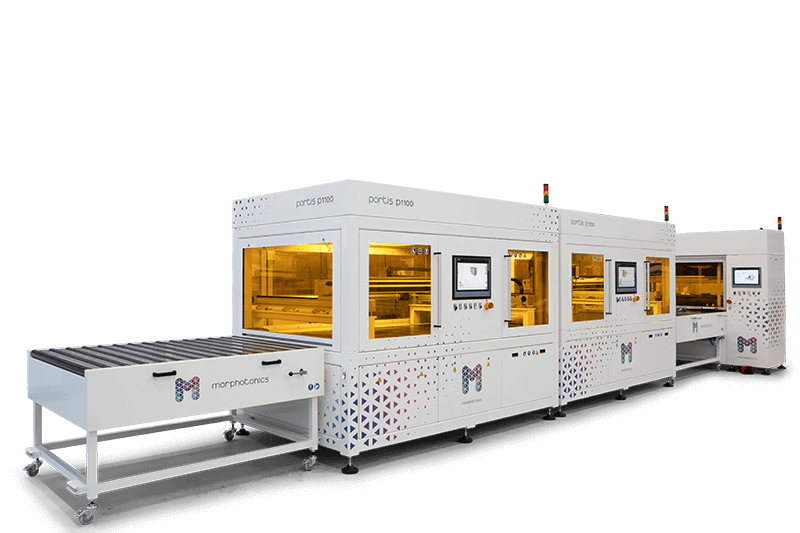

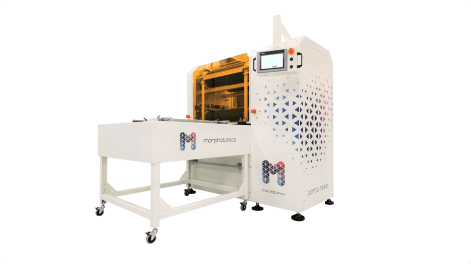

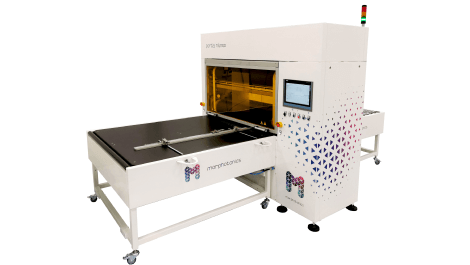

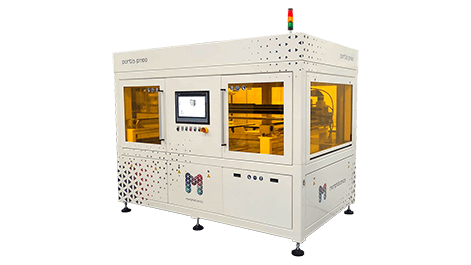

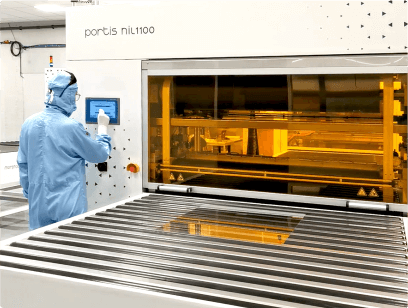

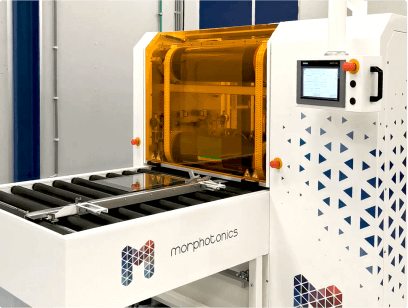

Portis

Introducing the ultimate in flexibility and convenience – our Portis Roll-to-Plate equipment with Coater (C1100), Imprint (NIL600 & NIL1100), and Primer (P1100) modules to fit your specific manufacturing needs.

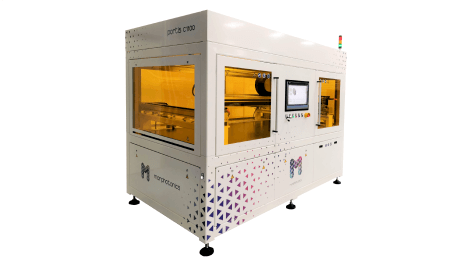

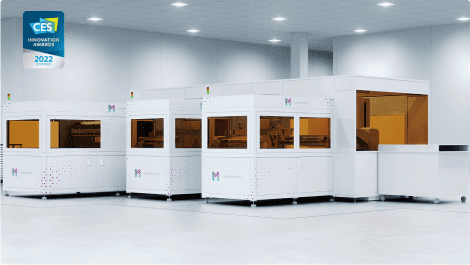

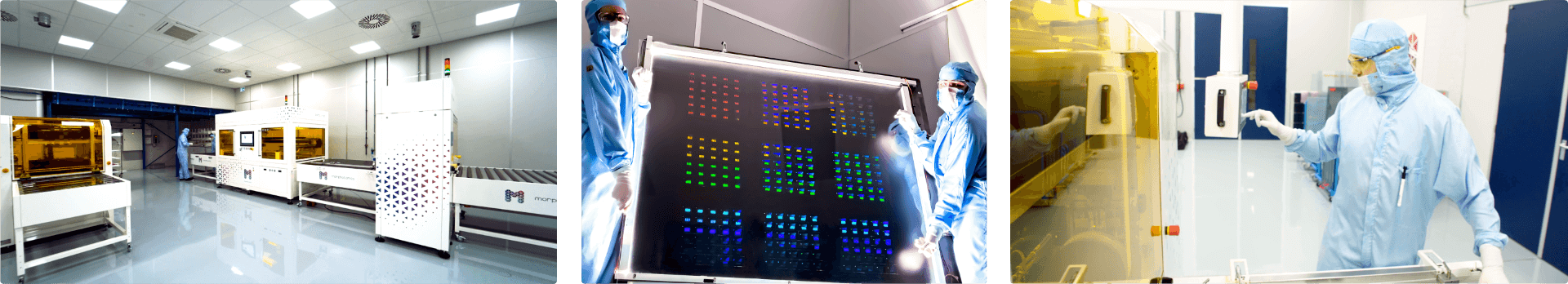

Aurora

Recognized as a CES 2022 Innovation Award honoree, the Aurora Roll-to-Plate nanoimprint lithography technology platform is a game changer for mass production. With its fully automated, highly accurate integrated modules working continuously, it can achieve imprint cycle times of under two minutes in mass production.

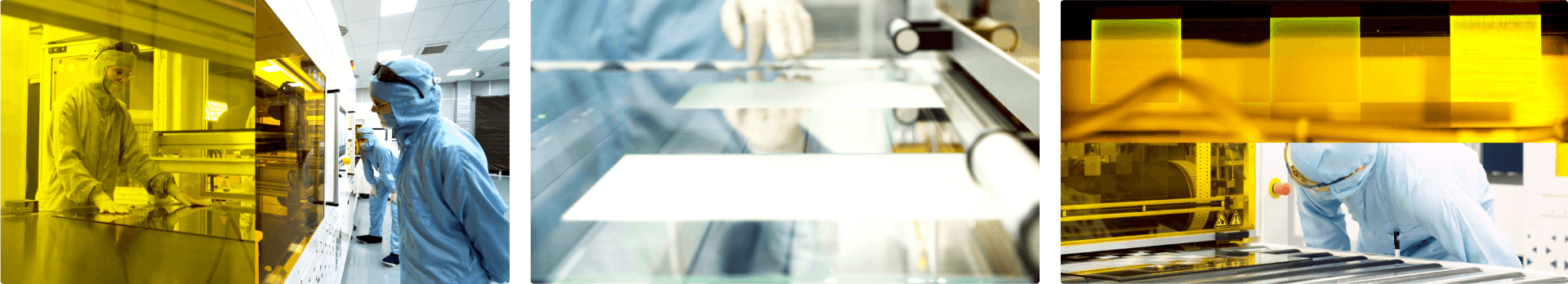

Diverse consumables portfolio

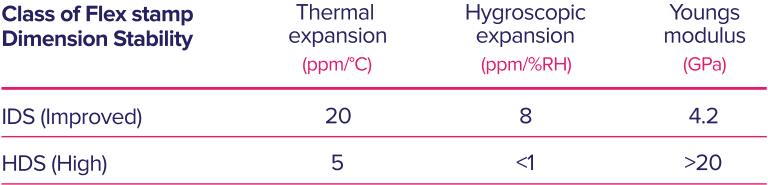

Highly reusable flexible stamps

Our flexible stamps (‘flex stamps’) are essential for ensuring the high quality imprinting of your products.

With high replication fidelity and tunable dimensional stability, our stamps guarantee accurate and consistent imprinting of your designed structures every time. And with customer demonstrated lifetime of over 1000 imprints, our flex stamps are both durable and cost effective.

Learn more

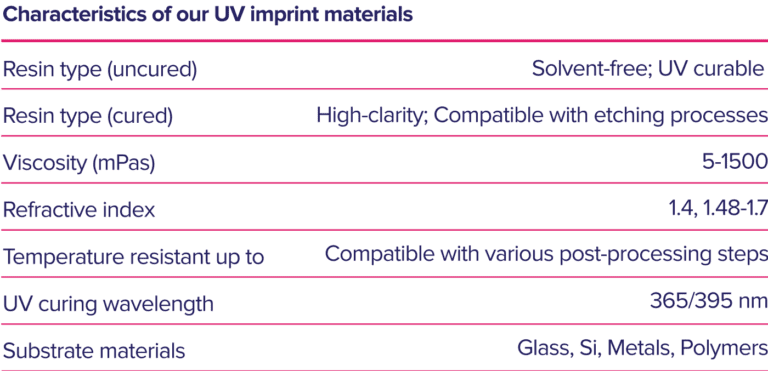

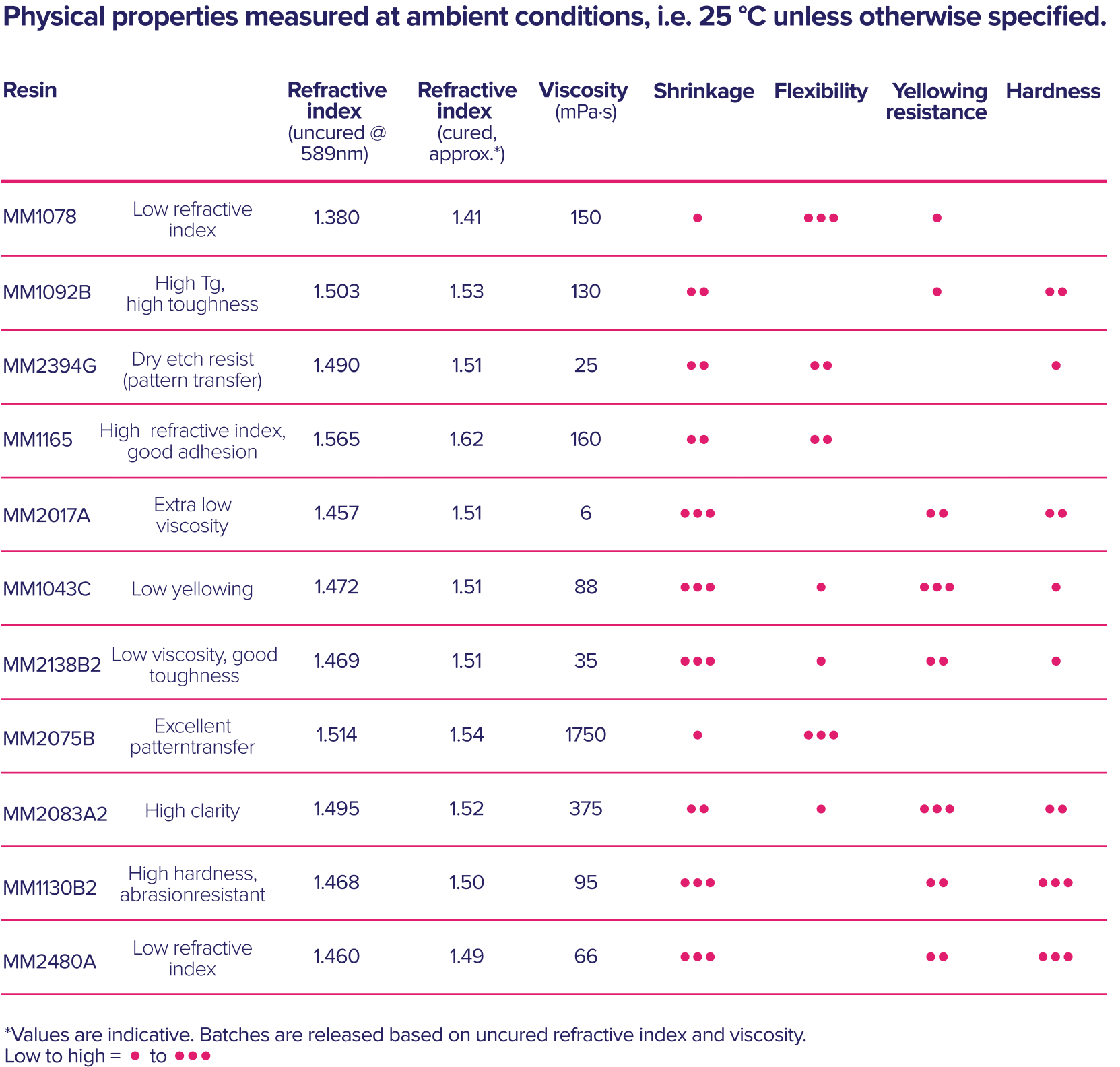

Proprietary nanoimprint resins

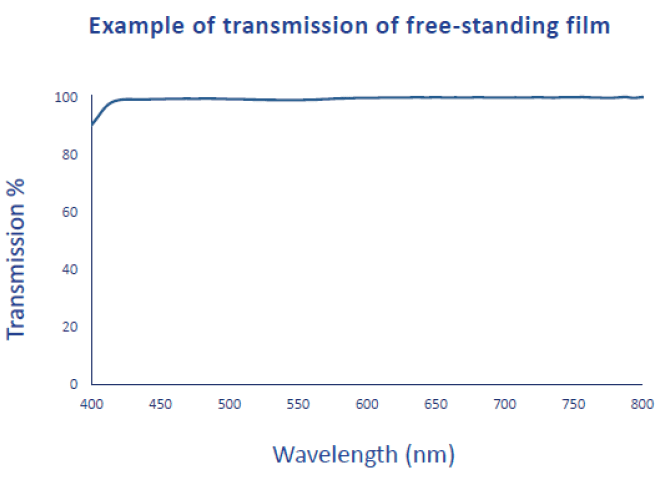

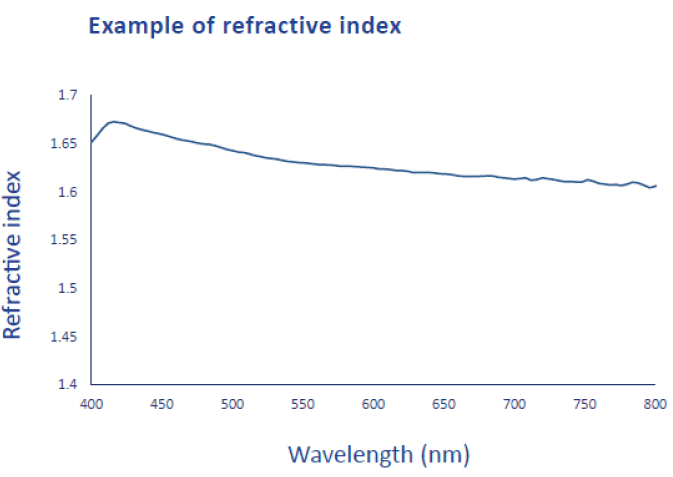

We understand the importance of using high quality UV-curable materials in nanoimprint lithography.

Our inhouse developed materials are designed to meet strict requirements and can be fully customized to fit your specific needs. Whether you need a permanent or a sacrificial layer, our materials are designed to enhance the performance and durability of your nanostructures and products.

Learn more

Want to keep up-to-date

with Morphotonics?

With our process expertise and innovative materials, we can help you achieve the full potential of nanoimprint technology for your specific needs.

To guarantee a successfully imprinted product, it is essential to carefully align the process settings with the chosen imprint materials. Given our in-depth knowledge of nanoimprint lithography equipment, we can expertly finetune the imprint parameters, such as speed and pressure, to ensure that your high-volume manufacturing needs are met with optimal results.

Curious about the basics of Morphotonics’ nanoimprint technology?

Dedicated

Software suite

At Morphotonics, our equipment is complemented with a suite of expertly designed and powerful software tools.

Our extensive range of tools empowers customers to pinpoint areas for improvement and utilize data-driven insights to optimize their processes and products. With our robust software tools, customers can seamlessly take full control of their equipment and more, for an enhanced experience.

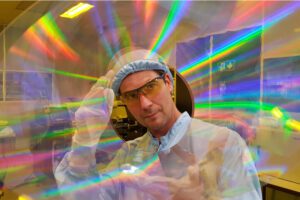

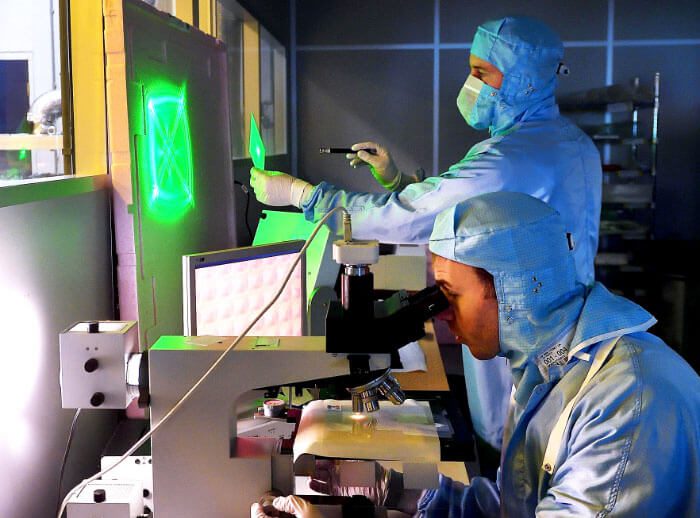

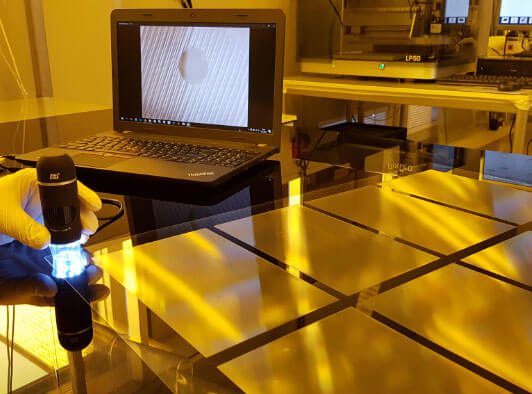

Our competence center supports you in every step

Our Competence Center allows for rapid prototyping and testing, enabling customers to make iterative design changes quickly and confidently to shorten their time to market.

We have 1000m2 of well-equipped cleanrooms with several Portis nanoimprint lithography lines and state-of-the-art metrology tools, to mirror the manufacturing process and help fine tune the transition to commercial production at our customer site.

Together we morph

dreams into reality

For more information, contact us.